Company Profile

Hangzhou Microcontrol Energy Saving Technology Co., Ltd. is a wholly-owned subsidiary of Hangzhou Shenshi Energy Saving Technology Co., Ltd., focusing on the research and development, production, sales and service of high-efficiency compact heat exchangers. The company is located in Singapore Science and Technology Park, Qiantang District, Hangzhou, and its production base is located in Jiande City, Hangzhou City. At present, it covers an area of more than 40 acres, has more than 480 employees, has special equipment production qualifications, has domestic leading vacuum diffusion welding technology, and is committed to low-carbon thermal management solutions under the national "carbon peak, carbon neutral" strategy . The company is in the fields of green energy such as LNG and hydrogen energy; in the fields of green power such as fuel cells, heat recovery power generation, and nuclear power; in the field of thermal management of power systems such as aviation, ships, and vehicles; in the fields of aerospace, base stations, and new energy vehicles It provides energy-saving and material-saving low-carbon heat exchange solutions for users' thermal systems.

Production equipment

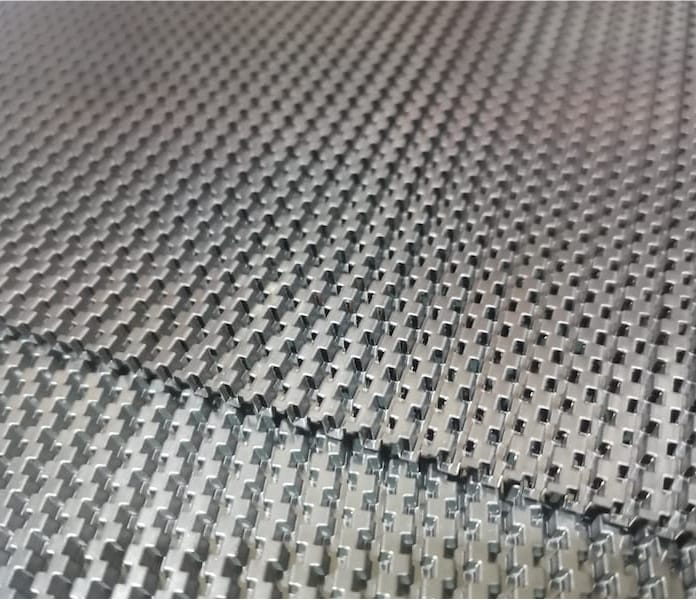

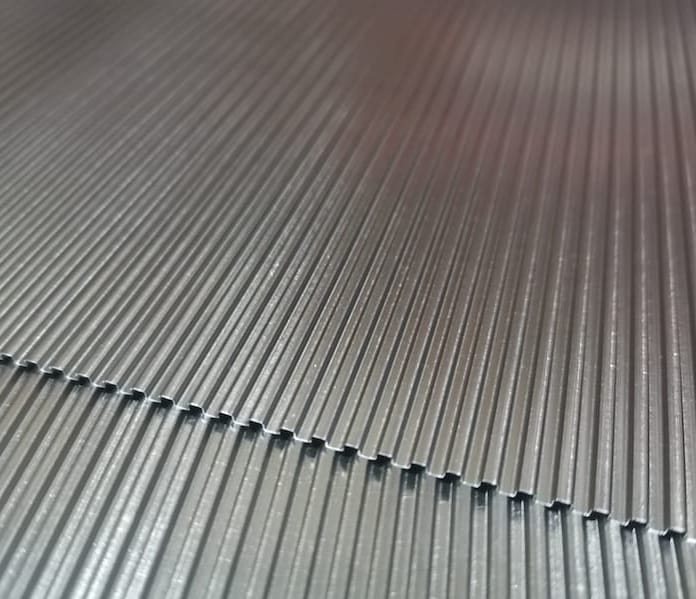

Hangzhou Microcontrol Production Base has the capabilities of machining, welding, assembly, testing and testing, and can develop and produce microchannel heat exchangers, microchannel cold plates, diffusion welded plate-fin heat exchangers, and microenvironment systems. The production base is equipped with vacuum diffusion welding furnace, high temperature brazing furnace, welding robot, wire cutting, machining center, laser cutting machine, automatic pipe bending machine, fin stamping forming machine and other processing equipment.

quality assurance

Hangzhou Microcontrol takes "commitment to quality and safety" as the core concept, from product quality to manufacturing industry, to employee safety, checks at every level and strictly manages. We strictly enforce the highest standards regarding health and safety. Hangzhou Microcontrol always puts customers first.

Diffusion welding technology

The principle is that after several layers of metal sheets with different thicknesses are processed through the flow channel and shape, appropriate pressure and temperature are applied in a vacuum state to fully combine the metal surfaces. The heat exchanger core made by diffusion welding technology has the advantages of no joints, no welds, and no other types of potential failure points. The strength after welding can reach more than 95% of the base metal. Guarantee the excellent performance of the product.

Design Calculation

According to the accumulated experience in calculation, simulation and test of micro-channel, plate-fin type and other products for many years, the calculation formula and correction coefficient were formed by fitting, which ensured the accuracy of the design, and explored and formed its own unique heat exchanger product design method. , which can provide reasonable and feasible design solutions according to different environments, appearances and heat exchange requirements.

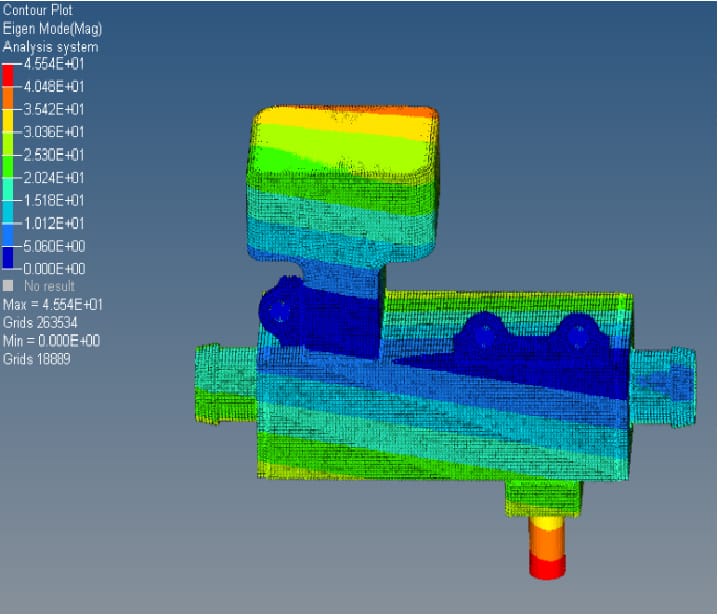

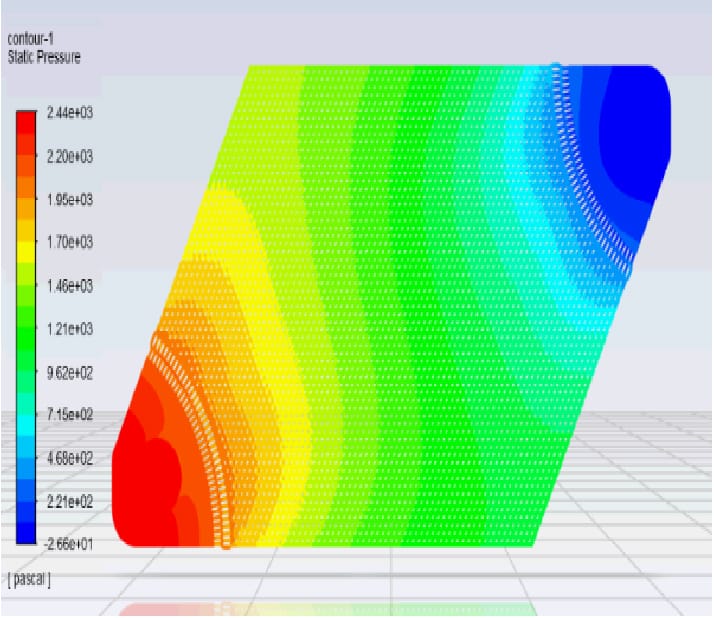

Simulation Technology

After a large number of simulation cases and actual delivered product test data, a set of targeted optimization simulation methods has been summarized and formed, which improves the accuracy and efficiency of heat transfer and flow resistance simulation. Micro-scale processing technology: Micro-channels (minimum equivalent diameter up to 0.1 mm) are processed on the substrate through micro-processing technology, which greatly increases the heat exchange area, makes the fluid form turbulent flow, and improves heat exchange capacity.

Company qualification certification

The company has fully passed ISO9001:2015 international quality system certification, ISO14001:2015 environmental system certification, UL/C certification, ROHS certification, CRAA certification, pressure vessel manufacturing license, EU CE certification and other qualification certifications, IATF16949 certification and DNV ship certification. Class society certification.

Previous

Next

Honors

The team focuses on the research and development of microchannel heat exchanger products, and a number of technologically developed products have won provincial and municipal awards and certifications.

Previous

Next

Company patent

Hangzhou Microcontrol is a domestic manufacturer of high-efficiency and compact printed circuit board heat exchangers and microreactors, as well as the first (set) industrialized microchemical continuous reaction equipment general contractor in Zhejiang Province. The company has complete product qualifications, and has now obtained relevant qualifications for national defense science and industry supporting production, DNV/special equipment production license (A2)/safety production standardization / measurement management system certification/ISO14001 certification/IATF16949, ISO9001 quality management system certification/standardized good behavior Certificate / PED certification / UL, ULC certification / ROHS and other certifications; 133 patents and 28 authorized invention patents have been obtained.

Previous

Next