Plate Fin Heat Exchanger (PFHE)

Description

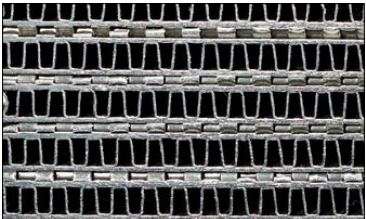

Plate fin heat exchanger PFHE are usually composed of baffles, fins, seals, and guide fins. Fins, deflectors and seals are placed between two adjacent partitions to form an interlayer. PFHE such interlayers are stacked according to the different ways of the fluid, and welded into a whole by special vacuum diffusion welding to form a plate bundle, that is, plate fins in the core of the heat exchanger.

Pressure resistance: 4-15MPa

High and low temperature resistance: -253~1000℃

Low leak rate: 1*10-9Pa m3/s

High reliability: secondary welding has no adverse effect on diffusion core body welds

Strong corrosion resistance: chlorine, acid, alkali, ammonia, mercury, etc.