Теплообменник с печатной схемой (PCHE)

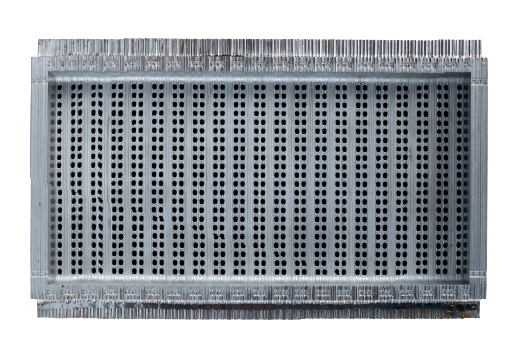

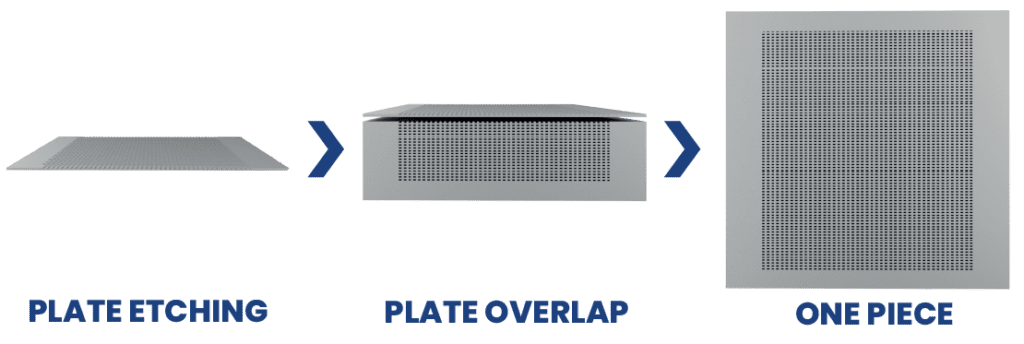

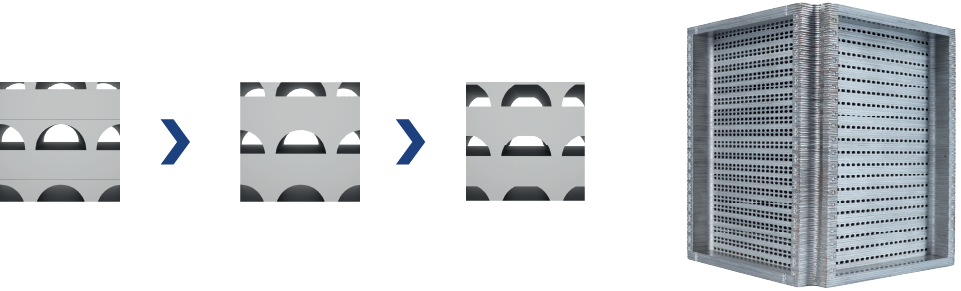

The PCHE is a compact heat exchanger formed by diffusion welding of multi-layer plates

TEMPERATURE

The special production process makes the product resistant to -196oC to 1000oC

COMPACT

Volume & weight are only about 1/6 of the traditional shell & tube heat exchanger

heat transfer

High heat exchange efficiency area can reach 1000m²/m³

LIABILITY

Diffusion banding ensures the highest safety level, without leak risk

BONDING process

In a vacuum environment, the welding parts are tightly combined and maintained for a period of time under a certain temperature and pressure. So that the atoms between the contact surfaces are mutually diffused to form a connection welding method.

Characteristics of diffusion welding:

(1) The bonding strength can reach more than 95% of the strength of the bonding material matrix;

(2) No filler metal is required, so the bonding temperature and corrosion resistance depend on the materials to be bonded;

(3) The joint has no remelted as-cast structure, rarely changes the physical and chemical properties of the raw materials, and the joint has no heat-affected zone;

(4) The glued product has only slight plastic deformation and small residual stress. It can be processed and cleaned after bonding. It is an ideal bonding method for precision parts.

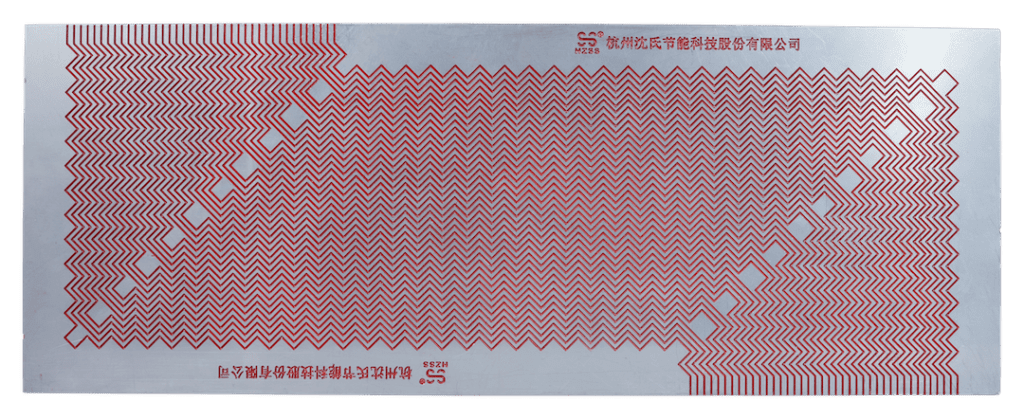

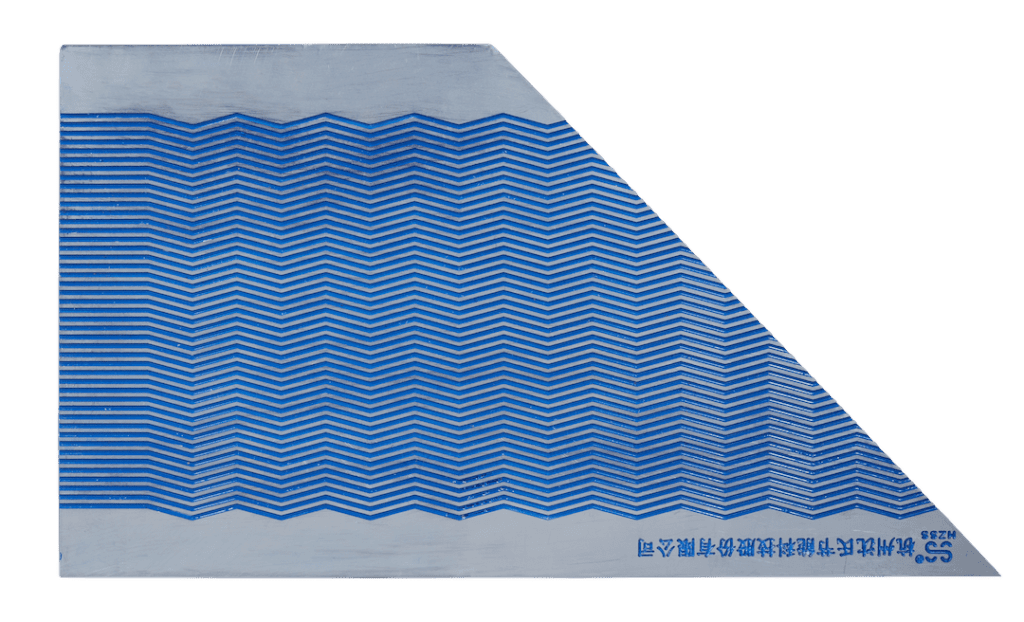

Heat exchanger with a variety of runner arrangements

* it can realize the design of multiple runner combinations

[3d_viewer id="5808"]