On September 22, 2020, President Xi Jinping delivered an important speech at the general debate of the 75th United Nations General Assembly, giving China’s position and China’s plan to face and resolve global threats and challenges. Xi Jinping pointed out that China will increase its nationally determined contribution, adopt more effective policies and measures, strive to achieve a peak in carbon dioxide emissions by 2030, and strive to achieve carbon neutrality by 2060.

According to public information, in the first three quarters of 2021, the power industry emitted a total of 3.756 billion tons of carbon dioxide, accounting for about 45% of the country’s total emissions. Therefore, to achieve carbon peaking and carbon neutrality, the energy and power industry has heavy tasks and great responsibilities, and will assume the main role.

Recently, the 2nd Symposium on Supercritical Carbon Dioxide Cycling Power Generation Technology was held in the form of video. More than 700 experts and scholars from domestic and foreign power companies, scientific research institutions, universities, etc. participated. The meeting arranged 40 high-level reports, including keynote reports, special invited reports and youth innovation forums. The meeting focused on discussing the technical status, research progress and challenges of SCO2 power generation.

CO2 is a colorless, odorless, non-flammable, non-toxic and stable gas. When it is above critical conditions (critical temperature 31.05 °C, critical pressure 7.38 MPa), CO2 presents a state of coexistence of gaseous and liquid states. In this state, the density and compressibility of CO2 are similar to that of liquid, but the viscosity is similar to that of gas, and the thermal conductivity and specific heat capacity are larger than those of gas, and it has the characteristics of high density, low viscosity and low compressibility.

Supercritical carbon dioxide (SCO2) cycle power generation technology is a major transformative frontier technology in the field of thermal power generation in recent years, and it is booming. The technology uses carbon dioxide as the circulating working medium, and has the significant advantages of high thermoelectric conversion efficiency, compact power equipment, small size and high flexibility, and can better adapt to some harsh requirements of new power systems. It is expected to be used in next-generation nuclear reactors and coal-fired power plants. , waste heat recovery and renewable energy (solar energy, geothermal energy, etc.) have been applied on a large scale, which is of strategic significance for the realization of low-carbon power development.

Compared with traditional units, the supercritical carbon dioxide power generation cycle system has the following advantages:

High efficiency: 600℃ power generation efficiency is 3-5% higher than traditional units

Flexible: 0-100% deep peak shaving, 5%/min lifting load rate

Low carbon: Oxygen-enriched combustion Allam cycle, combined with carbon capture and storage technology, can achieve zero carbon emissions

Compact: no condenser, compressor/turbine/motor (104rpm + heat exchanger (>1000㎡/m³)

The SCO2 cycle power generation system is mainly divided into simple heat recovery system and recompression system:

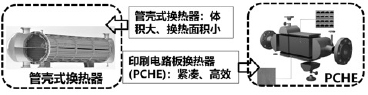

It can be seen that the heat exchanger is the key equipment to realize the heat transfer process in the SCO2 cycle power generation system!

The PCHE developed by Hangzhou Microcontrol adopts the international advanced photochemical etching and vacuum diffusion welding process. It has the advantages of high temperature, high structural strength, high pressure resistance (up to 99MPa), high/low temperature resistance (-200℃~1000℃), strong corrosion resistance, small thermal resistance, low leakage rate, wide applicable medium, etc. It can adapt to complex working conditions. It effectively solves the operation problems of the heat exchanger under the conditions of high temperature, thermal shock, high life and low flow resistance, and has great application prospects in the SCO2 cycle power generation system.

Etching technology features: high efficiency, high precision, good surface condition, small deformation after processing, low stress;

Characteristics of vacuum diffusion welding: excellent welding performance, no flux addition, welding strength and corrosion resistance equal to the strength of the base metal

SCO2 Power System Cooler

Hangzhou Microcontrol Energy Saving Technology Co., Ltd. is a wholly-owned subsidiary of Hangzhou Shenshi Energy Saving Technology Co., Ltd. It is also a domestic manufacturer of high-efficiency and compact printed circuit board heat exchangers and microreactors, and the first (set) industrialization in Zhejiang Province. The general contractor of micro-chemical continuous reaction equipment, focusing on the research and development, production, sales and service of high-efficiency compact heat exchangers.

The company has domestic leading vacuum diffusion welding technology, and provides energy-saving and material-saving low-carbon heat exchange solutions for users’ thermal systems in green energy, environmental control, micro-chemical industries and other fields. , has obtained 133 national patents and 28 authorized inventions so far.