A microreactor is a three-dimensional structural element that can be used to carry out chemical reactions and is manufactured in a solid matrix by means of special microfabrication techniques. Microreactors typically contain small channel dimensions (less than 500 µm equivalent diameter) and channel diversity in which fluids flow and in which desired reactions are required to occur.

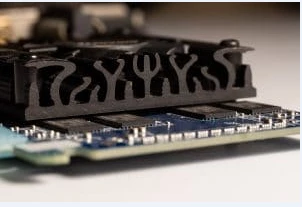

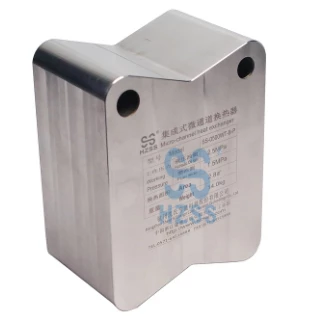

Microreactor equipment can be subdivided into micromixers, microheat exchangers, and microreactors according to their main purpose or function. The following picture shows the micro-reflector equipment developed by Hangzhou Shenshi:

Integrated microchannel heat exchanger, integrated microchannel cold plate, microchannel reactor, microreaction system device, etc.

Eurovantis — Empowering Your Journey in Smart Finance read more.

Although microreactors have been widely used in chemical process research and development, and their application in commercial production is increasing, it is difficult for the business community to define which reactions are suitable for which microchannel reactors, because each reaction The characteristics are different, and there are many types of microchannel reactor devices.

Taking the microreactor of Hangzhou Shenshi Energy Saving Technology Co., Ltd. as an example, the current Shenshi energy saving laboratory has been systematically screened, and now some experimental types suitable for microchannel reactors are listed: oxidation reaction, Grignard reaction, Grignard addition Reaction—elimination reaction, aldol condensation reaction, diazotization reaction, Baltz-Schiemann reaction, diazotization hydrolysis reaction, nitration reaction, etc.

One of the biggest problems facing all microchannel reactor equipment companies is the amplification effect in research and development. Theoretically, the microchannel reactor is amplified by quantity, and no amplification effect will occur. However, this is not the case in the actual operation process, because the simple use of quantity amplification will lead to very high equipment costs and control costs. This leads to the fact that in the actual scale-up process, it may be necessary to adjust the channel size and the combination of the reactors, and these adjustments are extremely likely to cause changes in the specific surface area, transfer characteristic length, and residence time distribution of the microchannel reactor, resulting in actual production. There is a deviation between the process and the small test experiment.

Another problem is the adaptability of the process flow. Due to the problem of flux, the microreactor will have problems in the connection between the pump selection and other subsequent sections. For example, if the throughput of the microchannel reactor is small, it may lead to subsequent processes, such as rectification, which simply cannot select suitable equipment. This has to turn the subsequent process into a batch process or needs to add a buffer unit between the two processes.

The corrosion problem of microchannel reactors cannot be ignored, and the corrosion resistance requirements are higher than those of conventional reactors. We know that the channel size of the microchannel reactor itself is very small.

Corrosion standards in conventional vessels are still too low for microchannel reactors. For example, the corrosion allowance in our conventional container can take a relatively large value such as 0.1mm/a. As long as the structural strength is guaranteed, it can be used normally. However, the inside of the microchannel reactor is the same, the channel is originally small, and no matter how strong the corrosion is, the characteristic size of the channel will change, and even internal leakage will occur. Therefore, the requirements for corrosion of microchannel reactors are more stringent, especially for metal reactors, the corrosion test must be considered before production.

As an emerging field, new types of microreactors still need to be developed, especially in the amplification law and industrial application of microreactors, which need to be greatly strengthened.