In today’s modern industry, electrical thermal management is much more than that. In addition to keeping electrical enclosures cool, thermal management is critical to many other important processes. As thermal management plays an increasingly important role, it becomes even more important for companies to find and implement more simplified solutions to this problem. In many cases, these solutions take the form of modern heat exchangers designed to produce high-performance cooling at the lowest cost to the company.

The role of thermal management in modern operations

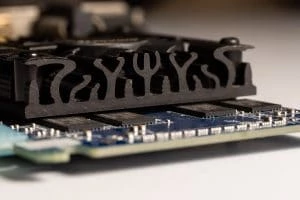

Thermal management has been an important part of these businesses since companies first started relying on technology for the bulk of their business. Most forms of technology utilize electricity, which means that their components generate electrical waste heat to some extent. Traditionally, the primary role of thermal management has been to prevent electrical waste heat from accumulating inside enclosures that house electrical components. However, technology is so dominant these days that even the simple role of keeping the case cool becomes cumbersome without the right electrical cooling solutions. Fortunately, heat exchangers have long provided companies with a more efficient and cost-effective way to maintain high-performance thermal management.

How Heat Exchangers Can Simplify Thermal Management

The reason traditional cooling solutions are often unwieldy is that the processes they use to implement electrical cooling are heavily energy and maintenance-dependent. Solutions such as air conditioners and air compressors use cool air to stop waste heat build-up, which is costing companies more and more as they become more reliant on technology. To solve this problem, heat exchangers handle electrothermal management differently. Instead of cold air, they prevent waste heat build-up by absorbing and transferring heat in a continuous cycle. Using environmentally friendly coolants to transfer heat within advanced heat exchangers can help companies save most or all of their thermal management processes.

The effect of heat exchangers on productivity

When companies rely on heat exchangers instead of more traditional air conditioners or air compressors, the benefits are huge. Not only do heat exchangers require less energy, but the equipment they use is simpler and easier to maintain. Since heat transfer is driven by natural processes such as natural/forced convection and phase change cooling, heat exchangers do not require the complex machinery used by older solutions. This means they don’t require as much routine maintenance and are far less likely to disrupt operations due to unscheduled repairs.