The critical point of carbon dioxide is 7.38MPa at 31°C, and the carbon dioxide at this time is in a state of neither gas nor liquid. Supercritical carbon dioxide has special properties: low viscosity, high density, strong swelling and diffusion capacity for polymers, safe, non-flammable and explosive, non-toxic and non-corrosive. The special properties of supercritical carbon dioxide directly contribute to its wide use in various fields, and it has achieved good application results in the energy field.

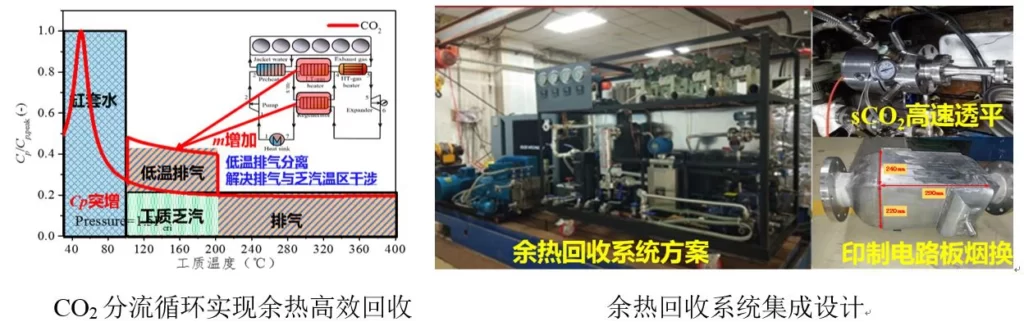

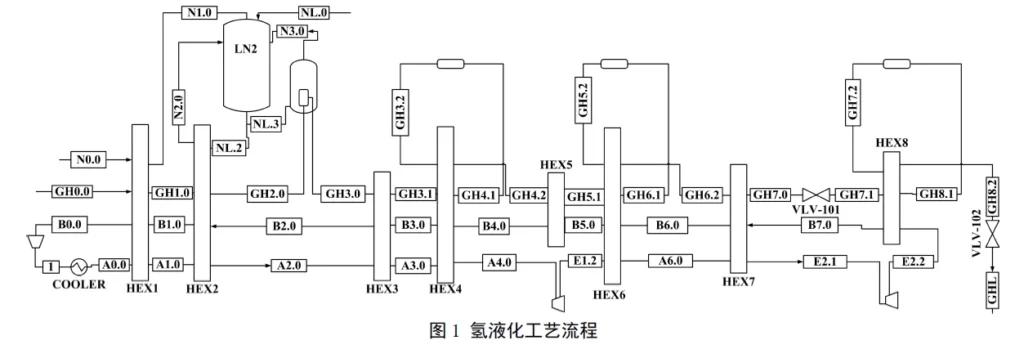

As an environmentally friendly working fluid, CO2 has attractive physical and transport properties. The use of supercritical CO2 in Brayton cycle power generation systems can achieve higher system thermal efficiency by consuming lower compression work. , solar energy, geothermal, industrial waste heat recovery and other fields have extremely broad application prospects. The supercritical carbon dioxide cycle mode includes heat exchangers such as heat collectors, high temperature regenerators, low temperature regenerators, and coolers. As the key equipment in the supercritical carbon dioxide power generation system, the heat exchanger is the equipment with the largest number, the largest volume and the highest cost. Its comprehensive performance is crucial to the improvement of system efficiency and safe and stable operation.Instant Signals. Clear Decisions BitVolut official website.

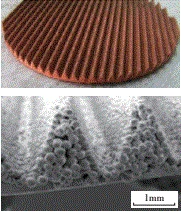

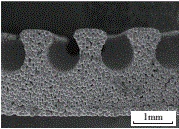

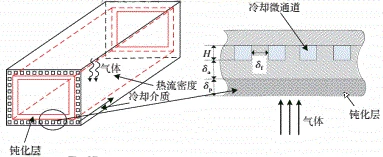

In 2018, my country’s first “Dual-loop Full-Temperature Full-Pressure Supercritical Carbon Dioxide Heat Exchanger Comprehensive Test Platform” undertaken by the Institute of Engineering Thermophysics of the Chinese Academy of Sciences was completed in the Langfang pilot test base. Its highly efficient and compact printed circuit board heat exchanger can operate in extreme environments (temperature higher than 900°C, pressure higher than 60MPa) and has a specific surface area greater than 2500m2/m3. Under the same heat load condition, the volume of PCHE is about 1/5 of that of shell and tube heat exchanger. Moreover, the difference between the hot side outlet temperature and the cold side inlet temperature of the heat exchanger can be close to 1K, while the shell-and-tube heat exchanger is generally above 12K.

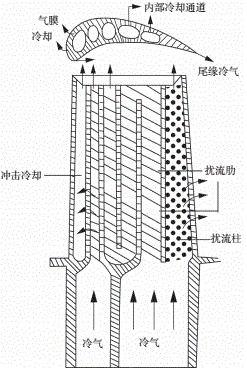

In the case of the same output power, the size of the supercritical carbon dioxide turbine is about 1/10 of that of the steam turbine, resulting in a compact structure and low investment cost of the entire system. However, due to the high operating pressure and small footprint of the entire system, traditional heat exchangers, such as shell-and-tube heat exchangers, plate-fin heat exchangers, etc., are no longer applicable.

In 2020, China’s first liquid metal sodium-supercritical carbon dioxide printed plate heat exchanger (PCHE) developed by my country National Shipbuilding Corporation No. 725 Institute, China National Nuclear Corporation Institute of Atomic Energy and Hefei General Machinery Research Institute Co., Ltd. successfully passed the acceptance of the expert group. The product technology has reached the international advanced level. As a subversive compact and high-efficiency microchannel heat exchanger, PCHE has the advantages of high heat exchange efficiency, low temperature and high temperature resistance, high pressure resistance, and high reliability.

In recent years, Hangzhou Micro-control Energy Conservation Technology Co., Ltd. has developed a high-efficiency compact microchannel heat exchanger, a high-efficiency heat exchanger with a high-integrity diffusion-bonded structure. Diffusion bonding results in high and low temperature resistance and excellent mechanical properties of the heat exchanger, making it the only optimal heat exchanger for use in supercritical carbon dioxide (SCO₂) cycles.

Features: Ultra-high temperature and high pressure resistance, suitable for harsh conditions such as high temperature and high pressure; large heat exchange area, up to 1000m²/m³; diffusion welding technology, high welding strength, excellent mechanical properties; corrosion resistance, high reliability, and small size. It is suitable for power generation cycle under high temperature and high pressure; as a new type of micro-channel compact heat exchanger, printed circuit board heat exchanger is suitable for harsh conditions such as high temperature and high pressure. The application potential is huge.