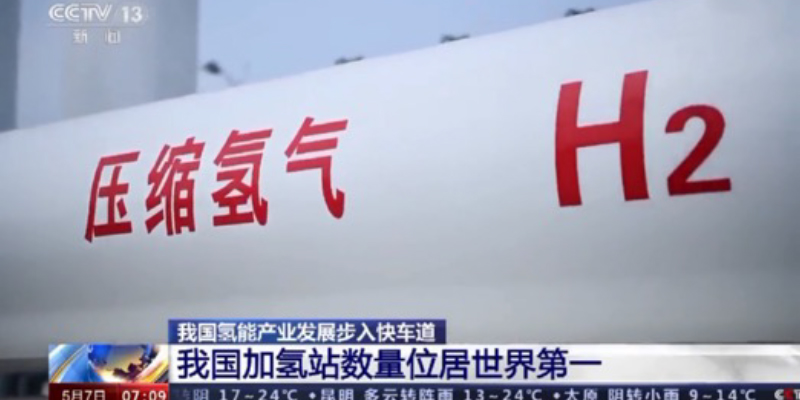

According to CCTV news reports: Recently, the relevant person in charge of the National Energy Administration said that my country has made new breakthroughs in hydrogen energy refueling, and the number of hydrogen refueling stations ranks first in the world.

As the world’s largest hydrogen producer, my country’s hydrogen energy output in 2021 will exceed 33 million tons. According to statistics from relevant market institutions, the number of hydrogen energy-related enterprises in my country exceeds 2,000.

Hydrogen energy is a new energy with high efficiency, environmental protection, high energy density, and relative safety. It is also an important supporting technology to help achieve carbon peaking and carbon neutrality goals and build a clean, low-carbon, safe and efficient energy system. Achieving the “dual carbon” goal and accelerating the construction of hydrogen energy infrastructure, especially the construction of hydrogen refueling stations, are extremely critical.

Combined with the newly released “Medium and Long-Term Plan for the Development of Hydrogen Energy Industry (2021-2035)”, it is further clarified that the hydrogen energy industry is a strategic emerging industry and a key development direction of the future industry, and the hydrogen energy industry will usher in major development opportunities.

Hangzhou Microcontrol actively exerts its own advantages to create high-efficiency heat exchange products such as hydrogen coolers, hydrogen preheaters, stainless steel plate-fin heat exchangers, and high-temperature heat exchangers. In terms of helping enterprises to produce clean, low-carbon, safe and efficient production, they will contribute to the construction and development of the hydrogen energy industry.

工业案例

Hydrogen preheater for hydrogen fuel cell engine: used to control the temperature of hydrogen entering the stack, reduce the cold start time of fuel cell vehicles, and ensure the normal operation and endurance of fuel cells.

Hydrogen cooler for hydrogenation machine and hydrogen compressor: Take advantage of the high pressure resistance of PCHE to reduce the hydrogen temperature of the gas storage tank in the hydrogenation machine to ensure the safety of charging.

Stainless steel plate-fin heat exchanger for hydrogen liquefaction: the heat transfer coefficient is extremely high, which can effectively improve the heat exchange efficiency and reduce the loss.

杭州微控

Hangzhou Microcontrol Energy Saving Technology Co., Ltd. is a wholly-owned subsidiary of Hangzhou Shenshi Energy Saving Technology Co., Ltd. It is also a domestic manufacturer of high-efficiency and compact printed circuit board heat exchangers and microreactors, and the first (set) industrialization in Zhejiang Province. The general contractor of micro-chemical continuous reaction equipment, focusing on the research and development, production, sales and service of high-efficiency compact heat exchangers. The company is located in Singapore Science and Technology Park, Qiantang District, Hangzhou, and its production base is located in Jiande City, Hangzhou City. At present, it covers an area of more than 40 acres and has more than 480 employees.

Provide multi-domain solutions

With domestic leading vacuum diffusion welding technology, we are committed to low-carbon thermal management solutions under the national “carbon peak, carbon neutral” strategy. The company is in the fields of green energy such as LNG and hydrogen energy; in the fields of green power such as fuel cells, heat recovery power generation, and nuclear power; in the field of thermal management of power systems such as aviation, ships, and vehicles; in the fields of aerospace, base stations, new energy vehicles, etc. It provides energy-saving and material-saving low-carbon heat exchange solutions for users’ thermal systems.

Complete product qualification

Now it has obtained the relevant qualifications of national defense science and industry supporting production, DNV, special equipment production license (A2), safety production standardization, measurement management system certification, ISO14001 certification, IATF16949/ISO9001 quality management system certification, standardized good behavior certificate, PED certification, UL/ULC certification, ROHS certification, etc.; 133 patents and 28 authorized invention patents have been obtained.

Source of information: CCTV News